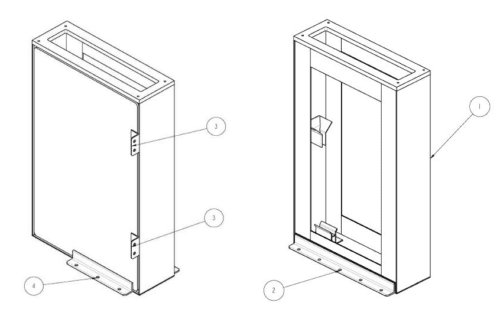

Neutron Shielding Walls

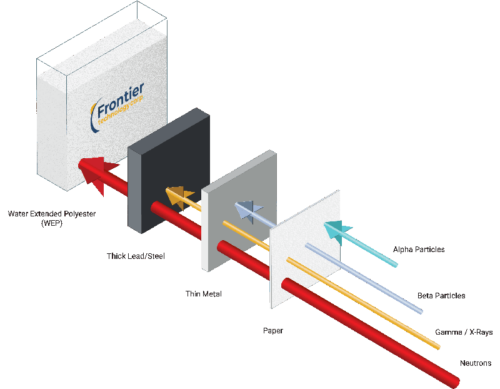

Our neutron shielding walls are ideal for use in nuclear reactors, medical facilities, research laboratories, and industrial sites. They are essential for maintaining operational integrity and ensuring the health and safety of personnel and the surrounding environment. Specially constructed neutron shielding walls are needed in any setting where neutron radiation is a concern.

In addition to nuclear power plants, facilities that commonly work with Californium-252 (Cf-252) neutron sources include PINS and PGNAA material analysis systems, research laboratories, and some industrial sites.

Frontier offers nuclear shielding options for a variety of industries and applications using our

Frontier offers nuclear shielding options for a variety of industries and applications using our