Why Shielding Walls Matter

Neutron shielding walls are an efficient and cost-effective way to block and prevent the damage caused by free neutrons emitted by Cf-252 and other neutron sources. Shielding walls are the first line of defense in facilities where neutron radiation is present. Whether it’s safeguarding workers in a nuclear research lab or shielding equipment and staff in a small modular reactor (SMR), effective shielding is critical to minimizing radiation exposure and maintaining regulatory compliance. Frontier’s shielding solutions are trusted worldwide because they deliver both superior protection and peace of mind.

What Is a Shielding Wall?

A shielding wall is a permanent or modular barrier designed to absorb and attenuate neutron radiation. These walls are critical in creating controlled environments where radiation levels must be kept below allowable exposure limits.

Unlike portable shielding devices, shielding walls are engineered for long-term, high-performance protection. They are often integrated directly into the structural design of the facility and can be customized to meet radiation shielding requirements in terms of thickness and layout.

"*" indicates required fields

Shielding Wall Solutions from Frontier

Frontier Technology Corporation specializes in advanced neutron shielding wall systems tailored to your specific needs. Our solutions are engineered to meet the highest standards of performance, reliability, and safety.

One key to effective neutron shielding protection is our proprietary NuWEP® product, a water-extended polyethylene material that slows fast neutrons and absorbs them. It offers many benefits for neutron shielding, including:

High Water Content: As a result of the emulsification process, WEP resin’s final hydrogen content is almost as high as that of pure water. Unlike water, WEP resin cures into a contiguous solid shape that fills its housing completely, so it can easily be used in almost any shielding application.

- Cost-Effective: NuWEP is a very affordable substance by weight compared to alternative materials.

- Harsh Environmental Resistance: WEP is completely inert. It doesn’t break down and resists damage from water exposure, weathering, and harsh chemicals. WEP is also fire-retardant (although best-suited for normal operating temperatures).

- Void-Free Curing: WEP resin sets cleanly and with minimal imperfections and no odor. It cures as a contiguous solid material with no voids, holes, or bubbles.

Frontier's Shielding Wall Capabilities

| Types: | Walls |

| Shielding | |

| Outer Material: | Stainless Steel |

| Inner Material: | Filled WEP (Water-extended polyester) |

| Thickness: | Custom Dimensions Available |

| Height: | Custom Dimensions Available |

| Width: | Custom Dimensions Available |

| Options: | Isotope Pass-Thru Ports |

| Production Volume: | Prototype |

| Production | |

| Testing Services: | Void Volume |

| Meter Testing | |

| Quality Control: | QA Manual |

| Additional Services: | Documentation |

| Integration | |

| Product Design | |

| Project Management | |

| Reverse Engineering | |

| Technical Support | |

| Project Lead Time: | 8-to-14 Weeks (based on inventory and scheduling) |

| Expedited Services Available |

Custom NuWEP Neutron Radiation Shielding Solutions

Frontier is a leader in the development and deployment of Water Extended Polyethylene (WEP) shielding solutions. WEP shielding wall panels combine the neutron-attenuating properties of water with the strength and stability of polymer composites. Our custom NuWEP solutions are ideal for clients who need highly specific designs without sacrificing shielding performance. From temporary enclosures to permanent installations, WEP technology delivers superior flexibility.

Download our Shielding Wall eBook To Learn More

Want to know what sets Frontier’s shielding walls apart? Our free eBook covers the best shielding wall materials, configurations, and real-world applications. Whether you’re designing for a lab, reactor, or SMR, this guide provides the technical insights you need.

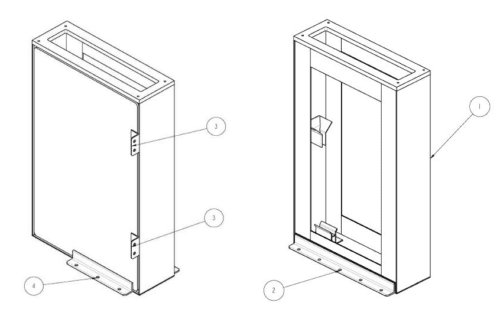

Design and Construction of Neutron Shielding Walls

Shielding walls are designed and fabricated to fit exactly where they are needed in a facility to effectively block neutron radiation and mitigate harm to people, objects, and structures in the area. They are customizable and adaptable for many settings; although, the exact dimensions of the WEP inside the hollow wall shells must be specified carefully to ensure effective shielding.

A major advantage of shielding walls is that they provide continuous shielding coverage over the entire surface area of the wall or group of properly connected walls. There are no gaps or changes in shielding performance because WEP is inert and stable, it will not shrink, melt, flow, or break down over time. This makes WEP-filled, steel-shell walls a long-term solution.

It is critical that walls maintain the structural integrity required for the application after filling without bowing or other physical changes. As long as this critical limiting factor is considered, most wall designs can be successfully filled. WEP can be molded into various shapes, widths, thicknesses to meet most needs. It is also important to include points for off gassing of water vapor or other gasses as the WEP cures.

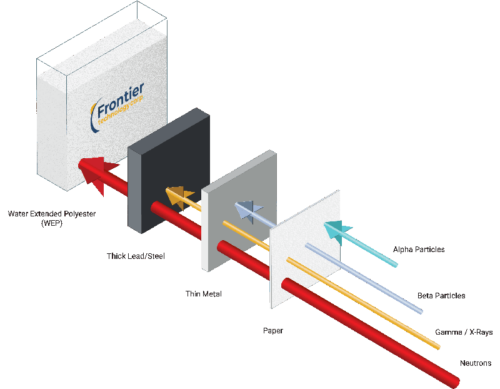

Elements Used To Slow & Absorb Neutrons

Neutron shielding and neutron capture take place at the atomic level, most often as a result of the neutrons’ interactions with two elements:

Hydrogen

Hydrogen is the most effective material for slowing fast neutrons to lower their kinetic energy into the thermal neutron range. This is because neutrons and protons have a similar mass, so when a fast neutron hits the single proton in hydrogen’s nucleus, the neutron’s kinetic energy is transferred, the neutron slows down, and it becomes a thermal neutron. For this reason, materials containing high levels of hydrogen tend to be highly effective for fast neutron shielding. In this application hydrogen is known as a neutron moderator.

Boron

Boron, and more specifically the B-10 isotope, is used to absorb neutrons so they cannot pass beyond the shield. This is because B-10 has a large cross section for neutron absorption (200 barn), meaning that it readily absorbs thermal neutrons into its nucleus. Fast neutrons generally are not absorbed because the more slowly a neutron is moving, the longer it is near the B-10 nucleus and the greater odds are of it being absorbed. After a neutron is absorbed into the B-10 nucleus Helium-4 and Lithium-7 are released.

Neutron Shielding Wall Materials and Properties

Several materials can be used to accomplish these two critical steps due to their naturally high levels of hydrogen and/or boron, or by adding these elements to them. However, some are more suitable than others in different applications. Some common shielding materials include:

Water

With a naturally high hydrogen content, water is an effective shielding material; however, the potential for evaporation and leaks make it a poor choice in high-temperature or harsh settings. When used in the large volumes required for adequate shielding, water-filled shields are very heavy and cost-prohibitive to transport.

Polyester, polyethylene, and other resin composites

These types of resins are high in hydrogen. In particular, water-extended polyester (WEP) resin is a lightweight, moldable material that is used to fill hollow structures, such as walls or panels for shielding. WEP has high mechanical strength and durability, performing well at temperatures up to 500°F (260°C), and it resists degradation from weathering or chemical exposure. WEP resin is mixed and poured into hollow wall structures or container shells and then allowed to cure. It sets cleanly and with minimal voids and has no odor, curing as a contiguous solid material. It can be molded into simple and complex shapes.

NuWEP Shielding Uses

Shielding is required any time a neutron source is in use or could come in contact with people. This includes shipping and transportation, short- or longer-term storage, as well as when the isotope is in use for nuclear or industrial applications. Shielding containers and structures usually consist of a mix of materials that work together to block neutrons from escaping. Examples include:

- Steel shipping/storage containers filled with water-extended polyethelene resin (WEP)

- Shielding walls that incorporate concrete and panels filled with water

- Other steel boxes or enclosures with WEP resin or concrete fillings

Industry Applications

Frontier’s neutron shielding walls are deployed across diverse industries. Each application benefits from customized engineering to ensure regulatory compliance and optimal protection.

- Nuclear Research Facilities: Shielding research reactors and particle accelerators.

- Defense and Military: Safeguard personnel and equipment in nuclear and weapons research.

- Nuclear Power Plants: Reinforce containment structures and create controlled access zones.

About Frontier Technology Corporation

Frontier Technology Corporation (FTC) is the world leader in californium-252 neutron source manufacturing and design, and is the foremost expert in logistics and shipping of radioactive material. Founded in 1984, Frontier Technology has over 40 years of industry experience in providing the highest-quality neutron sources, PINS sources, nuclear start-up rods, TYPE-A shipping containers, WEP shielding, and antimony-beryllium pellets.

Type-A Neutron Shipping Containers

Frontier designs and fabricates “Type-A” shipping packages of various sizes, shielding, capacities, and configurations for use, rental, or purchase by our customers. All packages are designed and constructed in-house to ensure that the highest quality standards are met.

Type-A Shipping ContainersWEP: The Best Neutron Shielding Material

WEP resin is a newer shielding choice valued for water’s high hydrogen availability. Due to its high content of large, neutron blocking hydrogen molecules, WEP is a highly effective shielding material. It also contains boron, an element that absorbs neutrons and adds additional shielding capability. WEP resin is strong, versatile, durable, and offers better neutron shielding performance than some high-density options.

WEP: The Best Neutron Shielding MaterialNuclear Shielding Applications

Neutron radiation poses significant danger to people, structures, devices, and equipment exposed to it; therefore, effective neutron shielding is critical. In plants, labs, and other buildings where neutron sources and equipment are used, shielding walls are an excellent way to protect against neutron radiation.

Nuclear Shielding Applications